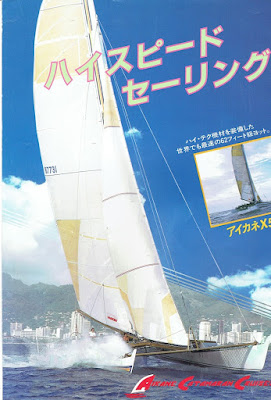

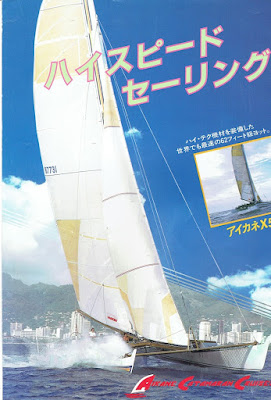

After arriving in Honolulu by airline for a change, I got a job with Aikane, Rudy Choy's company. Rudy Choy was one of the early pioneers in cruising and racing catamarans and I was pleased to be working for him. Aikane had three large tourist cats, two seventy footers and a one hundred footer, the Ali Ali Kai V. There was plenty of work maintaining and modifying them but the star of his fleet was the sixty foot Aikane X5. It was designed solely to break the speed record from Los Angeles to Honolulu. The X5 was equipped with large diameter aluminum pipe for the crossbeams. During the first attempt at the record, a crack developed in one of the four beams and they had to slow down and miss breaking the record. The decision was made to replace these with timber box beams. I went to work with stacks of birch plywood and Sitka spruce, just like the Spruce Goose aircraft. The photo below shows the X5 with the aluminum beams. I'm behind the spray on the jib sheet.

Crossing the finish line with a new record.

The next big project was a high performance tourist catamaran to be built for a hotel on the island of Kauai. We were going more high tech this time with foam core sandwich construction. The cat was to be 44 foot long and carry 30 passengers. It's not practical to build a female mold if there may be only one built so it was laminated with epoxy resin and Divinycell foam over a plywood male mold. The mold was well waxed and a layer of peel ply was put over it. The first layers of fiberglass are applied next followed by the 3/4" foam core which was held to the mold with a vacuum bag until the epoxy cured. Outer layers of fiberglass followed. The mold was built in two halves and the resulting hull shells are bonded together later.

One hull half coming off the black mold to be joined to the other half shell.

A vacuum bag bonding the foam core to the inner laminate.

The beam ends were machined into tapered splines. I molded a fiberglass socket over the ends of the beams so that the beam would slide into the socket and be locked against any rotation. The two bulkheads were angled for better stress distribution.

The finished product earning a living.

We built two of these Choy 44's and one was still working Waikiki beach the last time I was there.

Most of the previous catamarans designed by Choy had asymmetric hulls. The Choy 44's were symmetrical but a new client wanted the more traditional asymmetric model. He also wanted a solid fiberglass hull without a foam core. We did it in C-Flex since I had some experience using that material. Warren Seaman drew the mold sections for me and I got started.

The mold prepared for C-flex. To make the other hull, I disassembled the frame and reversed the molds.

Fiberglas layers applied.

The aluminum pipe crossbeams are the recycled ones from the X5 cut shorter with the cracked part removed.

Launching day.

We built two 60' Gougeon Stressform wingmasts. The 4mm birch ply sides

were scarfed into 60' panels. The central spar was Sitka spruce and

plywood with unidirectional carbon fiber on the spar caps.

The side panels are folded up over the spar and held with straps until the epoxy cures.

At the end of 1990, we moved to my wife's hometown in New Zealand.

Comments

Post a Comment